Why choose Genuine Atlas Copco spare parts?

Genuine air compressor parts & accessories are the only ones that are really designed for your compressor. By keeping your system integrity intact, they ensure the performance level you expect from your equipment.

The right air compressor spare parts at the right time

Every compressor part is subject to wear and needs to be replaced at specific intervals. As the manufacturer, we know exactly which oil-free, piston or screw compressor parts are needed, and when. We can offer them in a single package or service kit, saving you time and resources.

Air compressor oil for uptime and performance

We choose your air compressor oil carefully, depending on your application, site conditions, flow patterns etc. Our Syntethic compressor oils or Foodgrade oils extend your service life, compressor lifespan and performance.

Air compressor filters and separators

Avoid damage or performance loss in your air compressors. Keep away dust and dirt contamination with genuine air filter compressor parts and separators

Air compressor upgrades and Xchange

Working conditions can be hard for air compressors. When after years of operation, it’s time to replace a motor or element, you can insert the newest technologies for even better performance and energy efficiency.

Fixed Price services - Best compressor parts & maintenance

Avoid financial surprises. Our fixed price services combine the expertise of factory-trained technicians with the quality of our genuine compressor parts.

AIRnet - Compressed air piping system

AIRnet provides a complete compressed air distribution solution from start to finish. We continuously add and upgrade our products to ensure the highest efficiency of your distribution network.

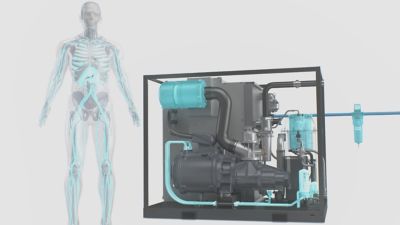

Single service supplier for your air compressor room

Our UNI compressor parts range is a complete offering of consumables and lubricants by Atlas Copco. UNI range spare parts have been designed to meet, or even exceed the OEM specifications. The range is developed with Atlas Copco's expertise, to our strict quality standards and it is continuously checked and updated to ensure a perfect match to the machines that use them.

Learn more about air compressor parts

Looking for tips and best practices from industry experts, or ways to increase your compressor energy efficiency?

Our blogs have all the answers.

Air compressor parts

Frequently asked questions

Find the answers on some frequently asked questions about air compressor parts. More information, how-tos and best practices you can always find in our air compressor blog

In order to make the right selection, the operating conditions of the compressor should be known very well. Temperature, air inlet quality and humidity play an important role in the selection of the right oil.

These parameters are described as the ambient conditions, and allow you to classify your application into mild, demanding or extreme. The selection of the right compressor oil depends on this classification of your application.

Learn more about compressor oil in our blog