Compressed Air Quality Class 1:3:0 is perfect for Food and Beverage applications!

For most food and beverage applications, Atlas Copco recommends compressed air with Purity Class 1:3:0 when measured according to the ISO 8573-1 standard.

This ISO standard is often misquoted and referenced by many in the industry who don't fully understand it. The standard is a very simple framework to define compressed air quality using a quality class system. Known as "ISO 8573-1:2010 Compressed Air - Part 1: Contaminates and purity classes," this standard has been used for decades and is a very handy reference document for specifying and verifying compressed air quality.

ISO 8573-1 specifies purity classes of compressed air with respect to:

For each of these contaminate types, the ISO standard sets quantifiable levels and assigns each level to a number. The lower the number, the better the quality level.

When these individual purity classes are combined, they form a sequence of numbers that defines the compressed air quality class according to the ISO standard and is expressed as ISO 8573-1:2010 [A:B:C] where:

- A is the purity class for solid particle

- B is the purity class for water

- C is the purity class for total oil

The below table shows the contamination limits for each Purity Class when measured according to test methods specified in other sections of ISO 8573-1:2010

To understand why Atlas Copco recommends compressed air with Purity Class 1:3:0 let's consider each potential contaminate in compressed air separately:

Particles can include sand, salt, sugar, black carbon, rust, cement, paint, skin flakes, and more importantly good food hygiene, spores, bacteria and even viruses.

This is the easiest contaminate to deal with and can be solved with simple but effective dust filters. Some F&B industry specific "best practice guidelines" recommend ISO 8573-1 Class 2 for dust, Atlas Copco recommends Class 1 instead. Most microorganisms will pass through Class 2 filters but will be effectively trapped by Class 1 filter sets. Dust filters are the lowest cost of all compressed air quality equipment so specifying Class 1 instead of Class 2 can reduce particulate count in compressed air by a factor of 20.

Particles can include sand, salt, sugar, black carbon, rust, cement, paint, skin flakes, and more importantly good food hygiene, spores, bacteria and even viruses.

This is the easiest contaminate to deal with and can be solved with simple but effective dust filters. Some F&B industry specific "best practice guidelines" recommend ISO 8573-1 Class 2 for dust, Atlas Copco recommends Class 1 instead. Most microorganisms will pass through Class 2 filters but will be effectively trapped by Class 1 filter sets. Dust filters are the lowest cost of all compressed air quality equipment so specifying Class 1 instead of Class 2 can reduce particulate count in compressed air by a factor of 20.

Particles can include sand, salt, sugar, black carbon, rust, cement, paint, skin flakes, and more importantly good food hygiene, spores, bacteria and even viruses.

This is the easiest contaminate to deal with and can be solved with simple but effective dust filters. Some F&B industry specific "best practice guidelines" recommend ISO 8573-1 Class 2 for dust, Atlas Copco recommends Class 1 instead. Most microorganisms will pass through Class 2 filters but will be effectively trapped by Class 1 filter sets. Dust filters are the lowest cost of all compressed air quality equipment so specifying Class 1 instead of Class 2 can reduce particulate count in compressed air by a factor of 20.

Particles can include sand, salt, sugar, black carbon, rust, cement, paint, skin flakes, and more importantly good food hygiene, spores, bacteria and even viruses.

This is the easiest contaminate to deal with and can be solved with simple but effective dust filters. Some F&B industry specific "best practice guidelines" recommend ISO 8573-1 Class 2 for dust, Atlas Copco recommends Class 1 instead. Most microorganisms will pass through Class 2 filters but will be effectively trapped by Class 1 filter sets. Dust filters are the lowest cost of all compressed air quality equipment so specifying Class 1 instead of Class 2 can reduce particulate count in compressed air by a factor of 20.

Water is naturally present in the atmosphere and so will also be present in compressed air. In most applications, compressed air is dried to reduce the chance of condensation in pipework and pneumatic devices. Compressed air with a Relative Humidity (RH) of less than 40% will eliminate condensation in compressed air systems which will prevent rust and prolong the life of pneumatic devices such as air motors, cylinders, actuators etc.

This level of dryness can be achieved with refrigerated dryers resulting in ISO 8573-1 Class 4 for water. However, food and beverage applications generally need a higher level of dryness to ensure food hygiene and safety. This is because air can contain microorganisms (bacteria, fungi etc.) which grow and multiply in the presence of moisture and nutrients.

Compressed air with a RH less than 20% is considered food and hygiene safe. We recommend ISO 8573-1 Class 3 for water. This corresponds to a PDP of -20°C or less and will generally deliver compressed air with a relative humidity less than 10%. This is well below the dryness level needed to protect food safety and avoiding hygiene hazardous.

Coupled with ISO 8573-1 Class 1 for particles which reduces microorganism count in compressed air by a factor of 20, Class 3 for water will inhibit growth of all living particles in compressed air.

Compressed air with a RH less than 20% is considered food and hygiene safe. We recommend ISO 8573-1 Class 3 for water. This corresponds to a PDP of -20°C or less and will generally deliver compressed air with a relative humidity less than 10%. This is well below the dryness level needed to protect food safety and avoiding hygiene hazardous.

Coupled with ISO 8573-1 Class 1 for particles which reduces microorganism count in compressed air by a factor of 20, Class 3 for water will inhibit growth of all living particles in compressed air.

Compressed air with a RH less than 20% is considered food and hygiene safe. We recommend ISO 8573-1 Class 3 for water. This corresponds to a PDP of -20°C or less and will generally deliver compressed air with a relative humidity less than 10%. This is well below the dryness level needed to protect food safety and avoiding hygiene hazardous.

Coupled with ISO 8573-1 Class 1 for particles which reduces microorganism count in compressed air by a factor of 20, Class 3 for water will inhibit growth of all living particles in compressed air.

Compressed air with a RH less than 20% is considered food and hygiene safe. We recommend ISO 8573-1 Class 3 for water. This corresponds to a PDP of -20°C or less and will generally deliver compressed air with a relative humidity less than 10%. This is well below the dryness level needed to protect food safety and avoiding hygiene hazardous.

Coupled with ISO 8573-1 Class 1 for particles which reduces microorganism count in compressed air by a factor of 20, Class 3 for water will inhibit growth of all living particles in compressed air.

Compressed air with a RH less than 20% is considered food and hygiene safe. We recommend ISO 8573-1 Class 3 for water. This corresponds to a PDP of -20°C or less and will generally deliver compressed air with a relative humidity less than 10%. This is well below the dryness level needed to protect food safety and avoiding hygiene hazardous.

Coupled with ISO 8573-1 Class 1 for particles which reduces microorganism count in compressed air by a factor of 20, Class 3 for water will inhibit growth of all living particles in compressed air.

Compressed air with a RH less than 20% is considered food and hygiene safe. We recommend ISO 8573-1 Class 3 for water. This corresponds to a PDP of -20°C or less and will generally deliver compressed air with a relative humidity less than 10%. This is well below the dryness level needed to protect food safety and avoiding hygiene hazardous.

Coupled with ISO 8573-1 Class 1 for particles which reduces microorganism count in compressed air by a factor of 20, Class 3 for water will inhibit growth of all living particles in compressed air.

Compressed air with a RH less than 20% is considered food and hygiene safe. We recommend ISO 8573-1 Class 3 for water. This corresponds to a PDP of -20°C or less and will generally deliver compressed air with a relative humidity less than 10%. This is well below the dryness level needed to protect food safety and avoiding hygiene hazardous.

Coupled with ISO 8573-1 Class 1 for particles which reduces microorganism count in compressed air by a factor of 20, Class 3 for water will inhibit growth of all living particles in compressed air.

Compressed air with a RH less than 20% is considered food and hygiene safe. We recommend ISO 8573-1 Class 3 for water. This corresponds to a PDP of -20°C or less and will generally deliver compressed air with a relative humidity less than 10%. This is well below the dryness level needed to protect food safety and avoiding hygiene hazardous.

Coupled with ISO 8573-1 Class 1 for particles which reduces microorganism count in compressed air by a factor of 20, Class 3 for water will inhibit growth of all living particles in compressed air.

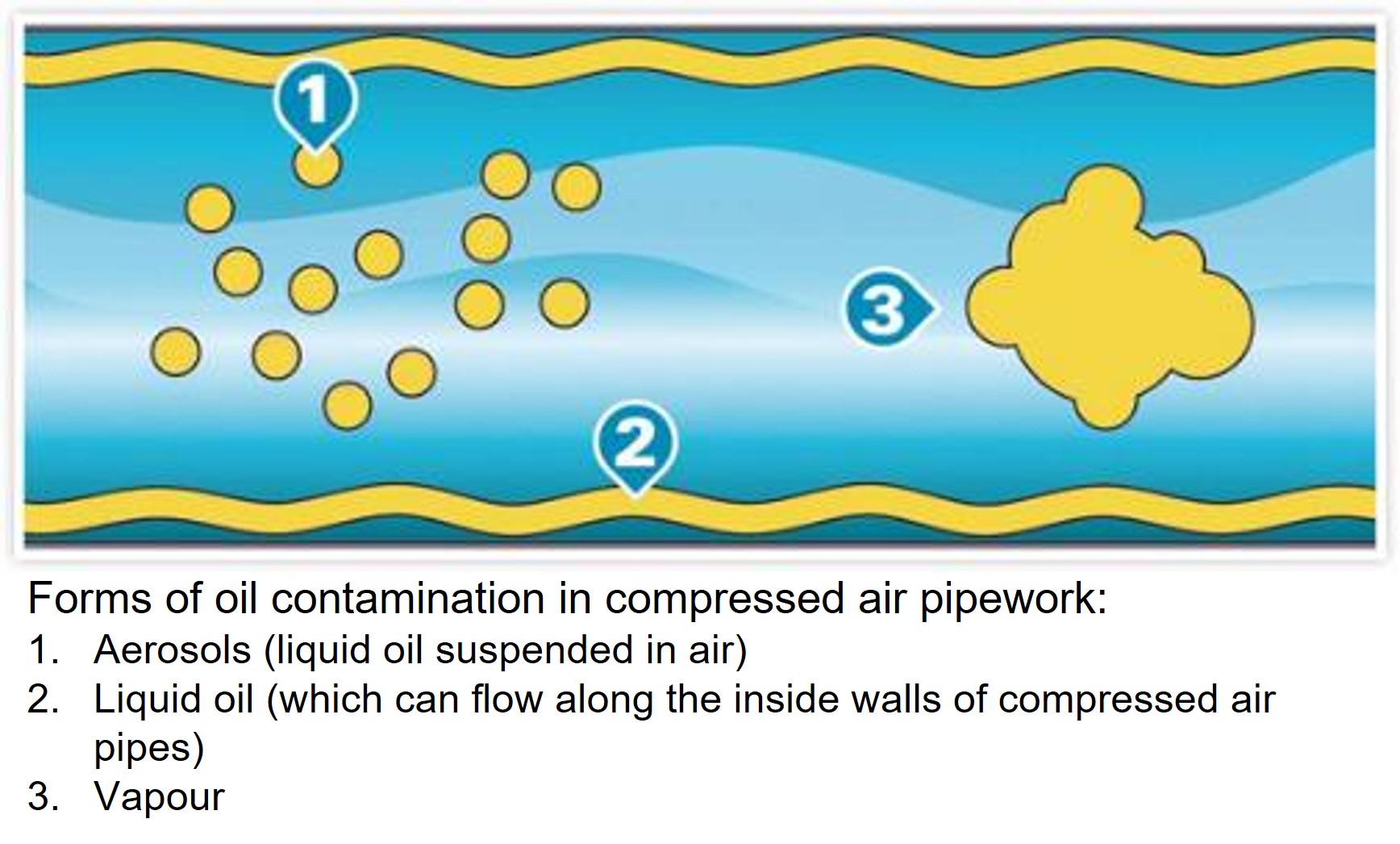

Whereas particles and water are naturally found in atmospheric air, oil is not. ISO-8573-1 defines total oil in compressed air as the mixture of oil aerosols, liquid oil and oil vapour.

According to the ISO standard, all forms of oil are defined as a mixture of hydrocarbons with 6 or more carbon atoms (C6+). These complex hydrocarbons are typically found in lubricating oil. So all oils are hydrocarbons but not all hydrocarbons are oil.

As a contaminate in compressed air, oil is the most difficult to manage. In a typical compressed air system with an oil-flooded air compressor (also called oil-lubricated or oil-injected), a system of up to 5 separate oil reducing stages are needed to minimise the degree of oil contamination in the compressed air.

5 Separate Stages of Oil Reduction used in a typical oil-flooded compressor system

Atlas Copco recommends ISO 8573-1 Class 0 for total oil. Oil does not have to be used in the compression process and there are many technologies available that produce oil-free compressed air. Such compressors can be independently tested and certified as Class 0 using the test methods recommended in various parts of ISO 8573 Standard even up to ambient air temperature of up to 50°C. No need for separators, coalescing filters and active carbon filters to manage oil contamination!

Atlas Copco recommends ISO 8573-1 Class 0 for total oil. Oil does not have to be used in the compression process and there are many technologies available that produce oil-free compressed air. Such compressors can be independently tested and certified as Class 0 using the test methods recommended in various parts of ISO 8573 Standard even up to ambient air temperature of up to 50°C. No need for separators, coalescing filters and active carbon filters to manage oil contamination!

Atlas Copco recommends ISO 8573-1 Class 0 for total oil. Oil does not have to be used in the compression process and there are many technologies available that produce oil-free compressed air. Such compressors can be independently tested and certified as Class 0 using the test methods recommended in various parts of ISO 8573 Standard even up to ambient air temperature of up to 50°C. No need for separators, coalescing filters and active carbon filters to manage oil contamination!

Atlas Copco recommends ISO 8573-1 Class 0 for total oil. Oil does not have to be used in the compression process and there are many technologies available that produce oil-free compressed air. Such compressors can be independently tested and certified as Class 0 using the test methods recommended in various parts of ISO 8573 Standard even up to ambient air temperature of up to 50°C. No need for separators, coalescing filters and active carbon filters to manage oil contamination!

Atlas Copco recommends ISO 8573-1 Class 0 for total oil. Oil does not have to be used in the compression process and there are many technologies available that produce oil-free compressed air. Such compressors can be independently tested and certified as Class 0 using the test methods recommended in various parts of ISO 8573 Standard even up to ambient air temperature of up to 50°C. No need for separators, coalescing filters and active carbon filters to manage oil contamination!

Atlas Copco recommends ISO 8573-1 Class 0 for total oil. Oil does not have to be used in the compression process and there are many technologies available that produce oil-free compressed air. Such compressors can be independently tested and certified as Class 0 using the test methods recommended in various parts of ISO 8573 Standard even up to ambient air temperature of up to 50°C. No need for separators, coalescing filters and active carbon filters to manage oil contamination!

Atlas Copco recommends ISO 8573-1 Class 0 for total oil. Oil does not have to be used in the compression process and there are many technologies available that produce oil-free compressed air. Such compressors can be independently tested and certified as Class 0 using the test methods recommended in various parts of ISO 8573 Standard even up to ambient air temperature of up to 50°C. No need for separators, coalescing filters and active carbon filters to manage oil contamination!

Atlas Copco recommends ISO 8573-1 Class 0 for total oil. Oil does not have to be used in the compression process and there are many technologies available that produce oil-free compressed air. Such compressors can be independently tested and certified as Class 0 using the test methods recommended in various parts of ISO 8573 Standard even up to ambient air temperature of up to 50°C. No need for separators, coalescing filters and active carbon filters to manage oil contamination!

The best possible quality of compressed air for use in food and beverage applications is ISO 8573-1:2010 Purity Class 1:3:0. This air purity class provides the best protection against contamination from particles (including microorganisms), water (to ensure food hygiene safety) and zero risk of any oil contamination.

To find out more, you are welcome to contact us by clicking the button below to fill out our form.